About company

Vertically-integrated mining-and-metallurgical holding. Our enterprices are located in 3 regions of Russia, in which work more than 17 000 employees.

Modern equipment and advanced technologies

High quality raw materials base

Supply capability to the European and Asian markets

Mission

Creating the metallurgy of the future

Factory

Tulachermet

Tula

Koks

Kemerovo

Kombinat KMAruda

Gubkin, Belgorod region

IMH-Vtormet

Tula

ShchZ KVOiT

Sovetsk, Tula region

Uchastok Koksovy

Kiselevsk, Kemerovo region

History of company

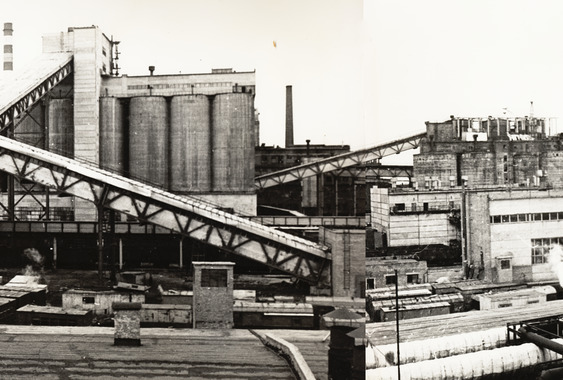

1924

March 2, 1924 launched the first coke oven battery of Kemerovo coke oven plant - now Koks PJSC is the parent company of IMH.

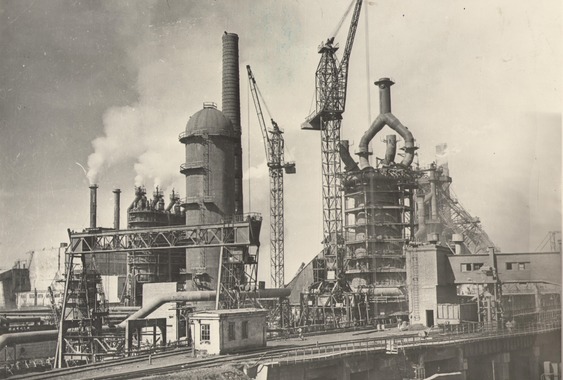

1935

June 15, 1935, the first blast furnace of the Novotulskaya Metallurgical Plant (Tulachermet JSC) is the largest enterprise of the IMH put into operation.

1952

February 23, 1952, by order of the Ministry of Energy of the RSFSR was created the Shchekino Auxiliary Boiler Equipment Plant - Shchz KVOiT.

1953

May 29, 1953, Kombinat KMAruda was formed, a key raw material asset base of IMH, a supplier of high-quality iron concentrate, developing ores from Korobkovskoye deposit of Kursk Magnetic Anomaly.

1960

August 23, 1960, an agglomeration plant was put into operation at Tulachermet, providing the enterprise with its own agro raw materials.

1969

May 31, 1969 started operation CPP Beryozovo-Biryulinskaya – now CPP Beryozovskaya, which is the Kuzbass coal-processing enterprise of IMH.

1993

Kemerovo Coke Chemical Plant was reorganized into Koks PJSC.

1999

The coal concentrate production facility at the CPP Beryozovskaya became part of the holding company.

At the Gubkin mine of Kombinat KMAruda began the experimental laying of waste rock filled and started filling of waste rock into the waste chambers of the mine - a unique environmental protection technology was launched.

2000

Koks PJSC has developed and installed special equipment for cleaning coke gas from ammonia using the circular phosphate method.

2002

Koks PJSC became the owner of the area for reclamation of the main field of the liquidated Vakhrushev mine. Uchastok Koksovy carries out reclamation with by-product coal mining.

2003

IMH received the authority of the individual executive body of the Tula Metallurgical Plant - Tulachermet.

Start of Tulachermet's pig iron sales on the American market.

2004

Development of coal assets is the entry into the Group of coal enterprises - Romanovskaya-1, Vladimirskaya-1, Butovskaya mines (now mined out/ pulled out from operations).

Tulachermet launched the country's first modern cast house BF-3 aspiration system with a two-fold reduction in specific blast furnace emissions.

2005

Acquisition of the site for the construction of the mine by S. D. Tikhov.

Introduction of a closed water cycle at Tulachermet.

2006

Kombinat KMAruda PJSC became a member of IMH.

2007

Coke furnace battery No. 3, one of the most modern and environmentally friendly in the industry at the time of commissioning, was put into operation at Koks.

The 100-millionth ton of pig iron was melted at Tulachermet.

2008

Blast Furnace No.1 is stopped for general overhaul of the 1st category.

2009

The introduction of water treatment technology at Koks eliminated the discharge of household and industrial wastewater.

The construction operations of S. D. Tikhov mine at the Nikitininsky coal field in Leninsk-Kuznetskiy has begun.

2011

The coal enterprices were divided into a separate subdivision in subjection to Koks-mining, which was renamed IMH-Ugol in 2016.

Start of cage and skip shafts construction and sinking of the underlying bottoms as part of the project to develop the Gubkin mine at KMAruda.

Processing line was put into operation for coal preparation of grate Ж at the CPP Beryozovskaya.

2013

Tulachermet realized the technology of melting low-phosphorus pig iron using coke Koks PJSC, as well as the use of coke nut in the operation of blast furnaces.

2014

Tulachermet stopped discharging all types of wastewater, because of the building of local treatment facilities.

2015

The production boiler house of the condensation power plant at Koks PJSC was built.

Start of large-scale technical re-equipment and modernization of the coal preparation process line at CPP Beryozovskaya.

2016

IMH has launched a corporate educational program called IMH Academy.

The 12 MW condensation power plant of Koks PJSC was put into operation and the first own electricity was obtained.

2017

A "Flare system" was extinguished over Kemerovo Coke Plant - combustion at the gas-collecting device was removed.

The S.D. Tichov mine is launched, mined scarce coal grate Ж.

2019

IMH-Vtormet, an advanced scrap metal enterprice, was launched in Tula; its main customer is Tula-Steel, a partner enterprise of IMH.

KVOiT delivered the first batch of roof supports for the Tikhov mine. The equipment is designed to work on coal seams with a thickness of 1.2-2.2 m.

2020

Start of the five-level corporate executive candidate pool program at all IMH enterprises.

Uchastok Koksovy received the permission to put into operation non-public railroad tracks. The enterprice financed two new tracks building with a total length of 2.5 km.

2021

IMH approved its sustainability policy.

The 15-millionth ton of coal was mined at the Uchastok Koksovy.

2022

Kombinat KMAruda completed construction of the shaft with the cage winding of the new mine with the complex of over-mine buildings. The shaft with the cage winding was driven to a depth of 454 m from the daylight surface. The purpose of the shaft is to lower and lift people, materials and equipment and to supply a fresh air flow.